Green Transformation in Mechanical and Plant Engineering

About the Study

For the study “Green Transformation in Mechanical and Plant Engineering,” we surveyed a total of 160 companies from the mechanical and plant engineering sector in Germany in the first quarter of 2022.

On a total of 56 pages, the study provides a detailed insight into this industry’s sustainability strategy.

In addition, we compare the results with important findings from the study “Green Transformation in the Automotive Industry” conducted last year.

Expert reports from Munsch Chemie-Pumpen GmbH and TRUMPF Machine Tools offer exciting impulses directly from the field.

Important on the path to a sustainable company is proactive action with a holistic climate strategy. At Dürr, we are actively reducing emissions and we act according to the motto invest don’t compensate.

Dietmar Heinrich

Chief Financial Officer/CFO

Dürr Aktiengesellschaft

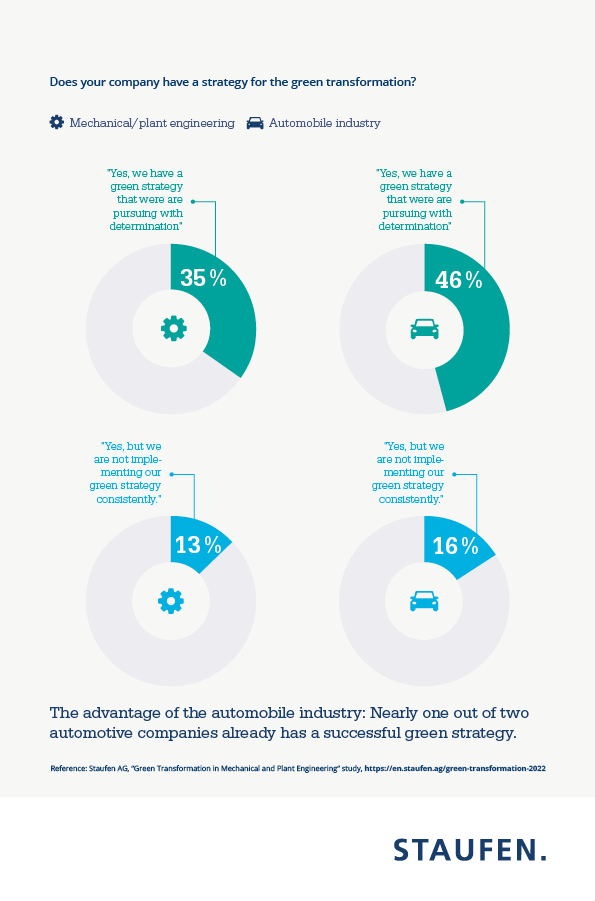

Does your company have a strategy for the green transformation?

The advantage of the automobile industry: Nearly one out of two automotive companies already has a successful green strategy.

Comparison of the results with the study “Green Transformation in the Automobile Industry” conducted last year.

There is a lot of software on the market. However, a comprehensive view of the suppliers’ information and the approval workflows is still lacking. Data is not made generally available so that it is useful.

Dietmar Borgards

Chief Procurement Officer, Member of the Executive Board

Kurtz Holding GmbH & Co. Beteiligungs KG

Feel free to contact us.

Mechanical and plant engineering must and will continue to drive ecological transformation. Central factors here will be the economic efficiency of the measures announced as well as stringent anchoring in corporate policy and management strategy.

We hope that this study will provide you with valuable ideas on how your company can successfully continue along this path, and we look forward above all to personally speaking with you.

Expert reports in the context of the study

“As a family-owned company, we always think and act with an eye on the next generation.”

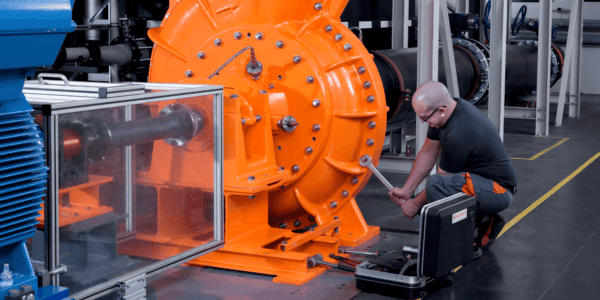

Munsch Pumpen, whose products are used especially in the chemical industry and for metallurgy, has been producing pumps since the 1960s. This company in the Westerwald is currently managed by Stefan Munsch, the family’s second generation. In the interview, this graduated engineer explains why sustainability was always writ large at Munsch and why he would sometimes like lawmakers to be a bit more practical.

“We’re contributing to the expansion of the circular economy and pushing system boundaries.”

The pressure on industry is growing: Politicians and the public are pushing for greater sustainability, while at the same time digitization is driving the cycle of innovation ever faster. Dr. Thomas Schneider, Managing Director of Development at TRUMPF Machine Tools in Ditzingen, Germany, explains in an interview how mechanical engineering supports the transition to a circular economy and the establishment of a green factory, and how business models are changing.