Businesses that are closely networked with their suppliers and partners benefit from the exchange and strengthen their future viability.

Thomas Spiess

Senior Partner, Staufen.Inova AG

Will global networks that can be successfully managed still exist at all in the future?

The number of partners involved in value creation has increased immensely across all levels. Networking and complexity will therefore continue to increase. These days, competition no longer takes place between individual companies, but between entire networks. Yet the events of the recent past have shown that the networks are more fragile than we thought.

Managing increasingly complex value chains is becoming an important competitive factor. Those who are victorious are those networks with sufficient and agile customer orientation. This is why Staufen has developed an approach for modern supply chain network management.

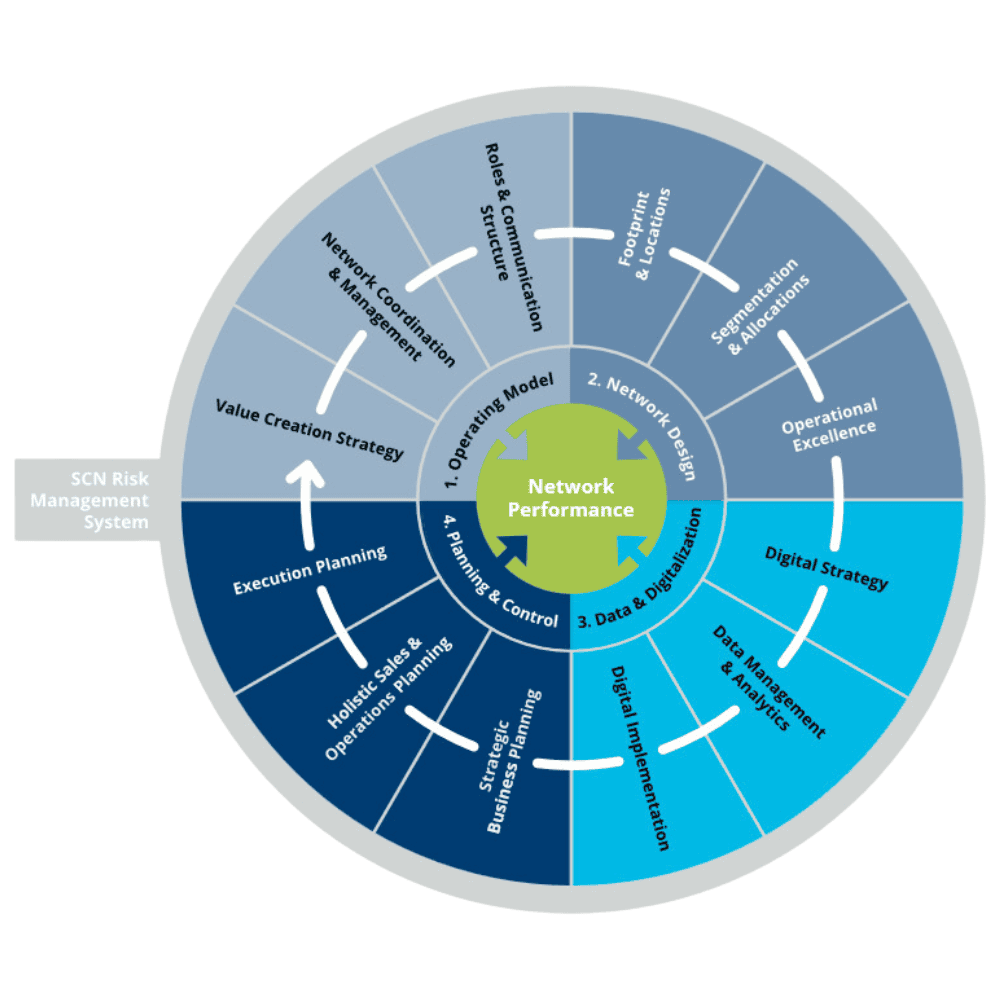

Staufen Supply Chain Network Management Framework

Central goal: make the entire network and the cooperation between the individual network partners more responsive, robust and efficient and thus improve the performance of the network.

In a world of increasingly intense pressures and threats, integrated supply chain network risk management is becoming much more important. This includes visibility and active monitoring of every kind of risk, for all levels of care, for all stakeholders, and all intersections of the network.

You can find all terms and explanations about our SCNM Framework in our SCNM Glossary.

Stabilizing the network requires cross-functional work in four dimensions

To meet these requirements, supply chain network management focuses on four key dimensions: operating model, network design, information system, and planning & control.

1. Operating Model

A supply chain network must be managed, controlled and strategically developed across the board..

2. Network Design

Deals with the configuration of all the different players along the value chain – end-to-end.

3. Data & Digitalization

The IT systems as business enablers ensure efficiency and transparency in the network while managing digitalized processes, digital networking, and business intelligence.

4. Planning & Control

Is essentially tasked with supporting all components in the network with the appropriate planning processes and establishing effective controlling..

The goals of a consistent supply chain network management

- Transparency on all network levels

- Increase of delivery performance

- Up-to-date data and data accessibility

- Alternative scenarios for critical areas and processes

- Implementation roadmap and prioritization of activity areas

- Monitoring and control system

YOUR EXPERTS FOR Supply Chain Network Management

We would be happy to support you in optimizing supply chain processes, structures or networks. Our international network of companies in Europe, Asia and America allows us to flexibly and quickly implement customer and market-specific tasks on a global scale.

Christian Ullrich

PrincipalSTAUFEN.AG

After his master studies in Industrial Engineering and Management at Karlsruhe Institute of Technology, he gained 8 years of consulting experience in supporting companies on their way to Lean Transformation. Furthermore he has international project experience in other European countries and experienced the management of projects for medium-sized customers and takeover of sub-projects for corporate groups. In reference projects he knows about the holistic OEE improvements in plant-intensive industries, introduction of Shop Floor Management, as well as coaching of executives in Shop Floor Management from team leader to managing director. Furthermore the introduction of a synchronized stand assembly incl. logistics connection in plant construction and factory planning projects (brownfield and greenfield). Complementary the design of cross-plant value streams and the optimization and design of assembly lines incl. connection to logistics.

Read more

Thomas Spiess

Member of the Executive Board

STAUFEN.INOVA AG

Phone: +49 7024 8056 0

E-Mail: kontakt@staufen.ag

Thomas Spiess

Member of the Executive BoardSTAUFEN.INOVA AG

Thomas Spiess holds a degree in Industrial Engineering (ETH Zurich), completed an MM Program at IMD Lausanne and is now a Senior Manager and Trainer at Staufen.Inova. He has extensive experience as an executive and senior consultant in the area of supply chain management with in-depth industry knowledge in the precision industry and the luxury consumer goods, textile and fashion industries. He has expert knowledge of complex global supply chain projects and concepts. He is also an accomplished moderator, trainer and coach.

Thomas Spiess has been in charge of projects for the overall optimization of international supply chains and is an expert in supply chain network management and sales & operations planning.

Our partners in the field of supply chain network management

Founded in 2000, River Logic is a global leader in supply chain strategy and planning. Companies across a wide range of industries rely on River Logic to help them solve complex trade-off decisions and optimize key growth, profit, service and other objectives. River Logic’s technology is based on a Digital Planning Twin™ that helps companies evaluate a range of end-to-end scenarios easily, quickly and thoroughly. This is not just about optimizing the network design, but the entire value chain through to the product portfolio, sustainability targets and the financial impact in terms of profitability and ability to finance operations.

STAUFEN IS ONE OF THE BEST IN “PURCHASING AND SUPPLY CHAIN MANAGEMENT”.

This is the result of the renowned industry study “Best Management Consultants 2024” by brand eins and Statista.

Supply chains have long since become complex networks, so collaboration between network partners must be constructive, and the network itself must be designed to be responsive, robust, and efficient.