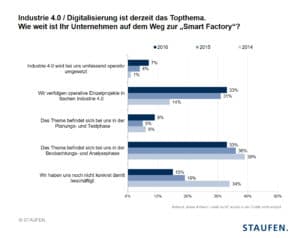

“At first glance, it might seem as if there had been a noticeable slowing-down in the speed of digital transformation over the course of the last year. However, this is nothing but a normalization in the development,” Thomas Rohrbach, Senior Partner at Staufen AG, puts these figures into perspective. “This is the consequence of ever more companies realizing that the objective of Industry 4.0 is not to create a complete smart factory from scratch overnight, but to take a considered and planned approach. Accordingly, only an exceedingly small number of companies have already digitalized and networked their entire value creation chain. However, the number of German companies that in operational terms have invested comprehensively in the Smart Industry has almost doubled compared to the previous year and now stands at 7 percent. Around a third of companies pursue individual operational projects and a further 40 percent evaluate potentials or have already reached the planning or testing phase. One can no longer deny that the future of industry has arrived in Germany: only 15% of those surveyed claimed that the smart factory played no role for them. While the main focus in the implementation of Industry 4.0 continues to be on areas close to the actual production process, 2016 shows a noticeable increase in indirect business areas. In research and development departments in particular, the topic is given ever greater importance: 44 percent have implemented relevant measures or are at least planning to do so in the near future. “Companies realize that Industry 4.0 is first and foremost an intellectual approach that has to encompass all of the developmental stages of a product or service,” Lean management expert Rohrbach explains. “Networking R&D activities with all corporate departments and external partners in combination with an improvement of processes at the same time is precisely the right way to shorten development times and reduce costs. In sales and distribution, too, about a quarter of companies already works in accordance with the principles of Industry 4.0 or plans to do so in the near future. This development is often driven by after-sales models. An intelligent product opens an entirely new area of value creation to companies that no longer, as in traditional industry, ends with the sales of the goods. In procurement, too, a new quality of digitalization and networking is beginning to prevail. About one in five companies is getting ready in this area for tomorrow’s industrial world. “The fundamental change in technology and thinking poses enormous challenges for companies in terms of technology, organization and human resources,” Staufen consultant Rohrbach points out. “For that reason, it is hardly surprising that most companies are taking a gradual approach.” Not even one in twenty companies of those interviewed for the German Industry 4.0 index thus calls into question everything across the board, in a “greenfield approach”. “A clear majority prudently combines the tried and trusted with the new”, as confirmed by Rohrbach’s observations of industrial practice. “Existing structures are refitted and reorganized, while new plants and locations follow the concepts of Industry 4.0 from planning onwards.” You can request a copy of the ”Industry 4.0 Index 2016“ by contacting:

Kathrin Kurz, k.kurz@staufen.ag Mechanical Engineering Congress in Salach (near Stuttgart) on 30 November 2016 Conditions within the global economy are shifting: mechanical engineering companies from Asia take over ever greater shares of the market and buy into their western competitors. Customers are looking for specific solutions; the demand for standard machines is dropping. On the other hand, service and other additional offers with respect to the actual product are becoming ever more important. Rapidly progressing digitalization offers many opportunities – but undeniably also risks. At the Mechanical Engineering congress, organized by Staufen AG in cooperation with the EMAG group and the VDMA Baden-Wuerttemberg, entrepreneurs and senior management will report on their experiences and successes, but also on their lessons learned. All information about the event can be found at:

www.maschinenbaukongress.de

Press release (.pdf) Press release (.rtf) Download the press graphic (.jpeg – in German)