Many companies strive for greater digitization in supply chain management to make logistics and delivery processes more efficient and robust. However, collecting large amounts of data is not enough anymore. The data and processes are too complex. “Smart applications” are therefore needed to reliably forecast sales and demand, optimize procurement processes and inventories, and reliably plan production.

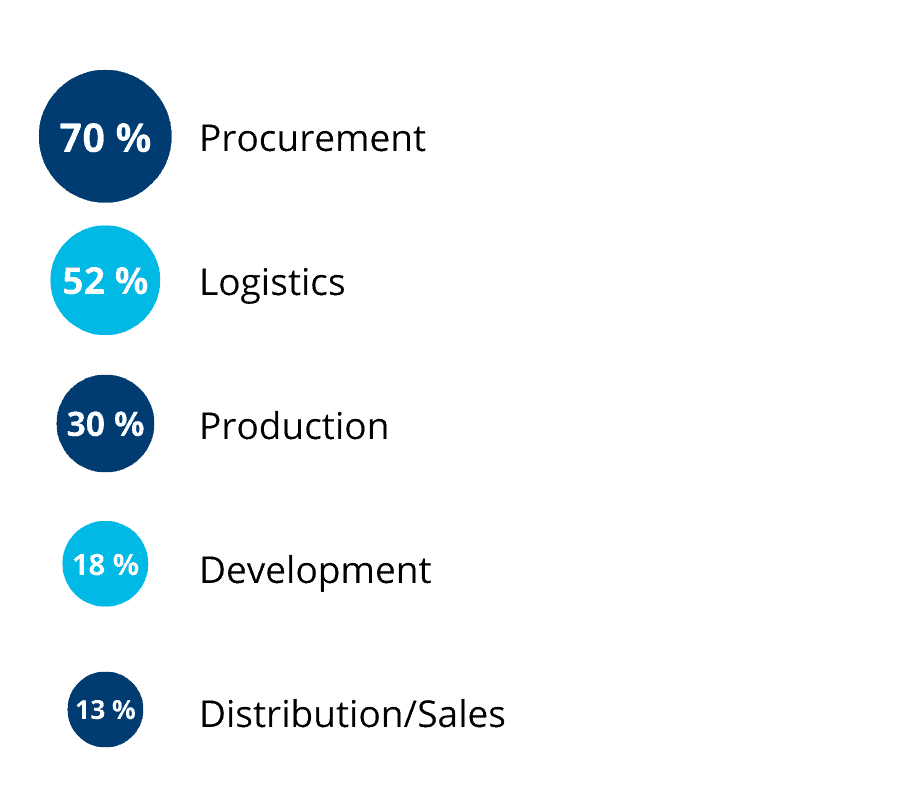

Where do you see the greatest benefit in digitizing your supply chain?

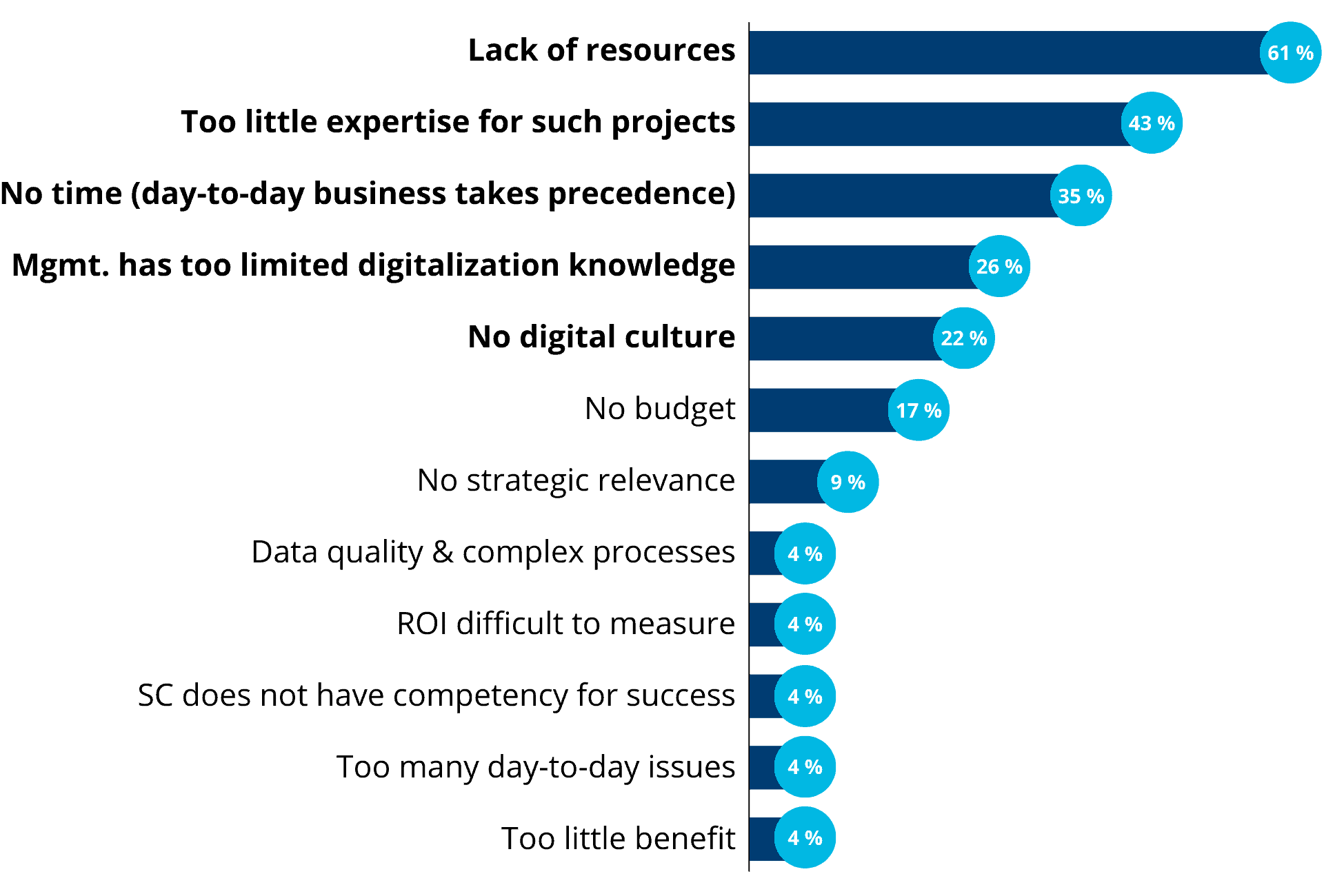

In which areas do you currently face the greatest challenges in your company?

Customer survey from Staufen.Inova as part of the event series “Supply Chain Analytics & Digital Supply Chain Management” (September 2020)

As part of Staufen.Inova’s “Supply Chain Analytics & Digital Supply Chain Management” event series in Zurich, we presented 5 key challenges of insufficiently digital supply chains.

Observed practice

Manual data entry and maintenance not only causes an enormous amount of work, but is also prone to errors and rarely results in up-to-date data sets. Employees still type up paper lists, manually transfer data between systems, and laboriously gather information or retrieve it from huge spreadsheets. With such data chaos, it is almost impossible to gain meaningful insights to optimize planning and improve decision-making.

Digital improvement potential

Digital data acquisition and interfaces between systems ensure a uniform, up-to-date and error-free database as well as smooth data flows. Intelligent applications are able to evaluate data in a targeted manner and optimize planning. This reduces the workload of employees, who can concentrate fully on decision-making and problem-solving. The system provides concrete indications of where action is needed and clearly presented data to make their work easier.

Observed practice

Supply chain management requires cooperation from different departments such as purchasing, logistics, production and sales. Therefore, process chains are long and many employees are involved. Accordingly, the need for coordination is great. Employees spend a lot of time in meetings and often have to ask questions by e-mail or phone. As a result, they take a long time to narrow down problems or make decisions. Along the entire process chain, delays occur again and again because information is missing.

Digital improvement potential

Digital applications manage data-based process control by automatically initiating the next processing steps and providing employees with all necessary information. At a glance, managers can see where and why parts are missing or how a future order will affect inventory. This means that less coordination and queries are necessary. Employees can make better and faster decisions. The entire company gains in agility.

Observed practice

For many decisions, employees lack a reliable foundation for decision-making. They simply do not know all the connections and dependencies:

- Does a new order affect the ability to deliver to regular customers?

- Is it a market opportunity that should be taken advantage of, or is it impossible to fulfill the order at all due to production capacities?

Ultimately, they do not make decisions based on data and insights gained from them, but rather according to a gut feeling or empirical values – and thus only rarely in an optimal manner.

Digital improvement potential

Digital solutions create transparency. They calculate re-procurement independently and provide employees with concrete recommendations for action in various scenarios as well as an overview of the effects of decisions. This enables the sales department to provide more precise delivery dates. Purchasing procures the required materials and raw materials in a timely manner. Production plans the necessary machine capacities at an early stage. All in all, the interaction between the departments improves considerably.

Observed practice

Only planning with ERP systems and Excel is often not capable of mapping complex processes in most companies. Sales, demand, and production planning are thus insufficiently coordinated. Any disruptions cause long interruptions in production because they require laborious rescheduling. Since minor disruptions in particular are common, employees operate more or less permanently in crisis mode.

Digital improvement potential

“Smart” applications that use AI techniques such as machine learning and mathematical optimization through operations research create optimized sales, demand, and production plans. These are already very robust by design, but also enable fast and perfectly adapted response to faults.

Observed practice

Poor planning often catches companies off guard with large safety stockpiles that cost a lot to transport, pack, and store. However, companies do not always have the right items in stock, and they do not always last indefinitely, so they will have to be discarded at some point.

Digital improvement potential

Digitally supported sales and demand forecasts can optimize safety stock levels. The company reduces its costs and prevents wasting goods, packaging materials, and energy. Self-set sustainability goals are much easier to achieve.

CONCLUSION

Many companies have now realized that they can reduce costs, increase delivery reliability, and improve production quality with digital solutions in supply chain management. This does not require companies to reinvent the wheel or develop applications on their own. Corresponding solutions are available on the market and deliver very good results after a short time.

Actually, there are no more excuses to postpone digitization of supply chain management any longer. Nevertheless, digitization projects in supply chain management are not making any headway. The top 5 reasons for this are lack of resources, lack of expertise, lack of time, lack of digitization knowledge, and a lack of digital culture. This is where the experts at Staufen can provide support.

Thomas Spiess

Member of the Executive Board

STAUFEN.INOVA AG

Phone: +49 7024 8056 0

E-Mail: kontakt@staufen.ag

Thomas Spiess

Member of the Executive BoardSTAUFEN.INOVA AG

Thomas Spiess holds a degree in Industrial Engineering (ETH Zurich), completed an MM Program at IMD Lausanne and is now a Senior Manager and Trainer at Staufen.Inova. He has extensive experience as an executive and senior consultant in the area of supply chain management with in-depth industry knowledge in the precision industry and the luxury consumer goods, textile and fashion industries. He has expert knowledge of complex global supply chain projects and concepts. He is also an accomplished moderator, trainer and coach.

Thomas Spiess has been in charge of projects for the overall optimization of international supply chains and is an expert in supply chain network management and sales & operations planning.

More about Supply Chain

What must future supply chain management be capable of? Part 2.

In the wake of the Corona crisis, global networks have had to make adjustments to increase their flexibility and respond to short-term fluctuations. But what challenges do innovative supply chains bring with them? With Thomas Spiess, member of the management board of Staufen.Inova AG, we discuss where companies have opportunities to connect and what proven solution strategies already exist.

Read more

The future of supply chains

Ole Trumpfheller from DB Schenker is convinced: customers and service-providers must adopt a collaborative approach to guarantee a secure and scheduled movement of goods in the future.

Read more

Supply Chain Network Management

The network of parties involved in the value creation process is becoming increasingly complex – especially due to the globalization of sales markets, production sites and procurement markets. Those who best master this complex value network and professionally manage the “customer-to-customer process,” i.e., make the goods available efficiently at the right time and in the right place, have a significant competitive edge.

Read more