Success Story Alstom

The French Alstom Group relies on Shop Floor Management and a new management culture in the construction of the new subway for the metropolis of Riyadh – and with great success.

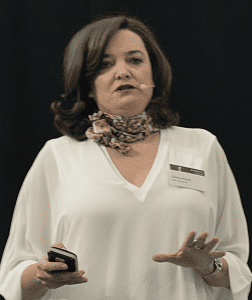

It does not take long for Cristina Anderiz to gain the attention of the entire hall at the RheinMain Congress Center, which has filled up to the last row. And that is not because she is one of the few women among the more than 300 participants of the 6th Engineering Summit. No – on this morning Anderiz, Riyadh Project Director at the French Alstom Group, captivates the who’s who of European plant engineers gathered in Wiesbaden, above all with impressive figures.

With 69 driverless trains that connect 27 fully air-conditioned stations over a distance of 63 kilometers, Alstom is responsible for about half of one of the world’s largest infrastructure projects: the construction of the new subway in the Saudi Arabian capital Riyadh. The order volume for Alstom alone is around €5.8 billion. Starting in 2021, the almost eight million inhabitants of Riyadh will have six lines spread over their 1798 km² metropolis (Berlin: 891.8 km²).

While Alstom is completing the trains in Katowice, Poland that will later drive autonomously, around 2,500 employees of the Group are in Riyadh working on the construction of the infrastructure for lines 4, 5 and 6 of the “Riyadh Metro.” Alstom is responsible for the energy supply, signaling technology and the platform screen doors. Together with employees from other companies who are carrying out the concrete work, for example, around 12,000 people from 40 different countries are working on Alstom construction sites – an XXL company spread over a city of millions.

When Cristina Anderiz arrived in Riyadh at the end of 2017 and took over the management of this mega-project, she quickly recognized the need for action. “Apart from language and cultural problems, there was a lack of transparency and standardization. In addition, many different approaches were used for planning and controlling, and there was no systematic improvement process or joint problem-solving,” says the experienced civil engineer. “We faced the challenge of setting up our team differently and moving away from silo thinking, so that the project could quickly move forward without sacrificing quality.”

Normally, it would have taken months to develop at least one plan for this Herculean task. Luckily, Alstom had already successfully applied the right solution: Shop Floor Management. In 2015, Alstom received the order from Deutsche Bahn to deliver 13 entire trains within 18 months. Thanks to its use of Shop Floor Management, the Salzgitter plant was not only able to deliver on time but was also given the “Supplier of the Year” award in 2016.

despite the complexity of the project, we now have very clear information flows and can quickly recognize where there are potential difficulties and how to precisely target them

Just like in Lower Saxony, Alstom decided to introduce Shop Floor Management (SFM) together with Staufen AG on the Arabian Peninsula.

In retrospect, Robert Farthmann, Partner at Staufen AG, sometimes marvels at what was accomplished in just nine months in Riyadh: “We had more than 200 individual coaching sessions, 12 team building events with a total of eight Staufen colleagues and conducted several workshops on process visualization and also implemented shop floor boards in each installation area.”

The level of success is impressive. For example, the time spent in meetings was cut in half, creating room for structured problem-solving. In addition, critical deviations are now reported to the responsible authority everyday in a fixed routine. “Despite the complexity of the project, we now have very clear information flows and can quickly recognize where there are potential difficulties and how to precisely target them,” said Alstom Manager Anderiz. It is important to her that is not about more strictly controlling employees. “On the contrary, with the current form of communication, we have established solid formats in which employees are able to make contributions and off er criticism.” She is therefore convinced that the experience gained in Riyadh will become the standard for Alstom projects in the future.

And what has changed for the top manager personally by implementing Shop Floor Management? After all, this method lives strongly on the fact that executives act as role models. “Shop Floor Management has helped me lead in a more precise manner and also channel emotions so that it really resonates with my team,” reveals Cristina Anderiz following her presentation at the Engineering Summit. So a Spaniard without emotions? “No, I would not go that far,” says Anderiz with a wink before flying back to Riyadh. After all, there is a subway waiting to be finished.