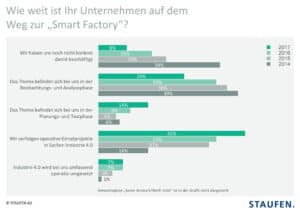

The German Industry 4.0 Index has continued to climb since Staufen Consultancy started collecting data for the index in 2014. This year, it reached a rating of 41 out of 100 possible points, its highest value to date. Almost all companies have recognized that they can no longer avoid digital transformation. Whereas last year, one-third of companies were still in the observation phase, now only one-quarter is making do with analyzing this potential. 48 percent of companies have actually already gone through the ensuing planning and test phase. They are either applying Industry 4.0 to individual projects or implementing it company-wide. Staufen Digital Neonex experts surveyed approximately 400 German companies for the German Industry 4.0 Index 2017.

Thomas Rohrbach, Managing Director of Staufen Digital Neonex, summarized the study results as follows: “Whereas last year, half of all industries were still taking a wait-and-see and approach, now almost two-thirds of companies are either actively planning or implementing digitalization.” Despite this positive development, there is still much potential for improvement. “The fact that the number of fully operational digitalized companies has remained the same is a clear indication that there are still very few pioneers that have truly followed the path of digital transformation in a consistent manner”, continued digitalization expert Rohrbach.

To this end, it is clear that German companies continue to concentrate their digital efforts on production. 85 percent of respondents already dealing specifically with Industry 4.0 are currently implementing “smart” concepts or are on the point of doing so. The automotive industry, with a value of 97 percent (electronics industry: 86 percent, mechanical and plant engineering: 74 percent), is very much in the lead. Logistics/warehousing remains at the same level as previous years. Production-related areas rank second, with a score of 56 percent. The comparatively high value of research and development shows that this area remains stable and that it is driven by Industry 4.0 in four out of ten companies.

This year, maintenance/after sales was introduced as a separate category for the first time in the service sector. Industry 4.0 already plays a role in at least one-third of these companies; overall, this new field ranks fourth. “Based on our study, it is possible that our annual comparison will show the streamlined service sector as having achieved the greatest growth”, explains Thomas Rohrbach of Staufen Digital Neonex. “In addition to predictive maintenance, the first companies are also working on new service offerings and business models within the context of Industry 4.0. Because this digital top-line is the key factor behind improving the value-creation position of German companies and opening up new potential for value creation, other companies should quickly follow in their footsteps.”

German Industry 4.0 Index 2017

For the German Industry 4.0 Index 2017, Staufen AG, together with Staufen Digital Neonex GmbH, surveyed a total of 394 German companies. More than 70 percent of the companies surveyed were from the mechanical and plant engineering, automotive and electronics industry. To receive a copy of the study, contact Kathrin Kurz, k.kurz@staufen.ag.

For press graphics (in German) on the topic of Industry 4.0, see drop down below.

About Staufen AG – www.staufen.ag

Inside every company is an even better one. This conviction has been the driving force behind our more than 20 years of providing consultant services and training to companies and their employees. Markets are continuously evolving and competitive pressure is high. Staufen helps companies quickly implement the right changes, increase productivity, improve quality and build their innovation capacity. The international lean management consultancy guarantees quick and measurable results using the appropriate strategies and methods. In order to increase the potential inside every company, Staufen consultants establish a living and sustainable culture of change together with management and employees. The Staufen subsidiary Staufen Digital Neonex supports mid-sized industries on the path to digital transformation. Staufen AG Academy also offers certified, practice-oriented training. More than 260 employees support customers across the world, from 13 international locations. The consultancy has been awarded the “Wirtschaftswoche” Best of Consulting award several times. In 2017, Staufen AG was the fourth-time recipient of the “Best Consultant” (brand eins Wissen) award.

About Staufen Digital Neonex GmbH – www.staufen-neonex.de

Staufen Digital Neonex GmbH is a Staufen AG subsidiary that supports mid-sized manufacturers on the path to digital transformation. In addition to introducing hands-on digital strategies for mid-sized companies, topics such as smart factory, data science and digitalizing product programs or business models are also part of the program. Staufen Digital Neonex does not leave participants to fend for themselves. Uncertainty and possible mistrust are minimized through customized qualification programs. Because Staufen believes that even in a smart factory, it’s the people who make the difference.