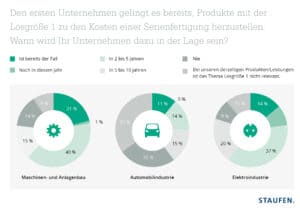

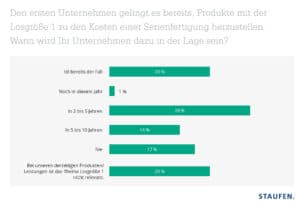

The unmistakable trend towards customization is still going strong in the field of production technology. A fifth of German manufacturing companies are already creating a batch size of 1 at the costs of serial production. Within no more than five years, another 28% want to have achieved this goal, with another 14% to follow suit in the next ten years. These findings emerged in the course of the German Industry 4.0 Index, which was recently released for the fourth time. Some 400 manufacturing companies in Germany were surveyed by Staufen corporate consultants.

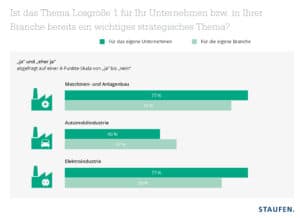

These figures reflect how companies view the future strategically: six in ten manufacturers see a batch size of 1 as a vital factor in the business success of their company and their industry. In one industry, however, there are remarkable deviations from this trend. The overall picture is very different in the automotive industry, a field which has actually already had major experience with at least partial mass customization. Here only 40% consider the batch size of 1 to be a strategically critical topic for their own company, and the consensus on an industry-wide level is only slightly greater. This skepticism may be due to the way the industry interprets its brands and products. After all, the consumer market is highly dependent on consumers feeling a strong sense of personal identification with a particular car model. And as a result, people still perceive their cars as being part of a series even though they have been heavily customized.

In keeping with this vision of their industry, the automotive industry also greatly underestimates the feasibility of a batch size of 1 in comparison to how other industries regard the topic. One fourth of companies does not believe that they will be able to create a cost-neutral batch size of 1. And over a third of those surveyed said that this issue had was not relevant to their business. “It is highly unlikely, however, that individual industries will be totally unable to turn their backs on the batch size of 1. As pioneers in the field move customization forward, more and more consumers will expect this development to be self-explanatory. What’s more, digital transformation is creating flexibility in production technology to an extent that could never have been predicted. Those who let today’s opportunities pass them by may never be able to maintain their current hold on the market,” as automotive expert Dr. Thilo Greshake warns.

The general situation is very different in the mechanical and plant engineering industry, where mass customization to fulfill client specifications has traditionally played a very major part. 22% of companies surveyed have already achieved a batch size of 1 or are on the verge of doing so, whereas another 40% will have done so in the next two to five years. Fewer than one in ten says that they do not believe that a batch size of 1 is relevant to their specific portfolio.

The electrical industry is only lagging slightly behind the mechanical and plant engineering sector in this area. But in both industries, there is consensus about the strategic relevance of a batch size of 1: a total of 77% cited it as an important issue within their own company. And 70% and 66% agreed that it was important to their respective industries as a whole.

German Industry 4.0 Index 2017

For the German Industry 4.0 Index 2017, Staufen AG, together with Staufen Digital Neonex GmbH, surveyed a total of 394 German companies. More than 70 percent of the companies surveyed were from the mechanical and plant engineering, automotive and electronics industry.

You can download the study and management summary here.

About Staufen Digital Neonex GmbH – www.staufen-neonex.de

Staufen Digital Neonex GmbH is a Staufen AG subsidiary that supports mid-sized manufacturers on the path to digital transformation. In addition to introducing hands-on digital strategies for mid-sized companies, topics such as smart factory, data science and digitalizing product programs or business models are also part of the program. Staufen Digital Neonex does not leave participants to fend for themselves. Uncertainty and possible mistrust are minimized through customized qualification programs. Because Staufen believes that even in a smart factory, it’s the people who make the difference.