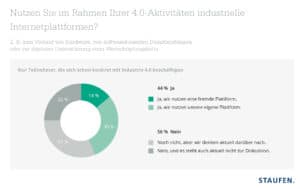

Not even half of the German companies that have already actively adopted Industry 4 is capitalizing on industrial internet platforms to distribute or support their value chain. And every fourth company is actually ruling out making use of this technology in the near future. These are the findings of Staufen Consultancy’s “German Industry 4.0 Index”. For the study, Staufen Digital Neonex experts surveyed approximately 400 industries in Germany.

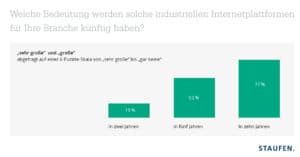

“Companies that refuse to use digital platforms are running the risk of totally missing out on developments that are key to their success,” warns Thomas Rohrbach, Managing Director of Staufen Digital Neonex. “Platform solutions such as these will become increasingly significant and companies will have no choice but to climb on board if they wish to survive – it’s only a matter of time.” Many companies are underestimating this trend, as highlighted by the study. On the one hand, 44 percent confirm that the platform issue is highly relevant, and another 38 percent at least acknowledge the potential. On the other hand, when it comes to assessing the speed of development, companies are still clearly stuck in an analog age: four-fifths doubt that industrial internet platforms will bring about noticeable change to their sector in the next two years. Even when looking ahead five years, almost half the companies are not overly concerned.

“Given the fact that opportunities such as these are currently springing up like mushrooms, this is clearly a case of deceptive confidence,” states digital expert Rohrbach. “A clear majority is not expecting industrial internet platforms to dominate for another ten years – an eternity in the age of digital transformation,” he warns. Whereas numerous companies are already using digital platforms for purchasing, in many cases, distribution in particular is often still hesitant. This is particularly due to an overriding fear – one that is not entirely unfounded – that platform providers could force themselves between the company and the clients. However, a certain lack of concern is also evident, given that the order books are looking really good right now. What is starting to emerge now is the how the purchase of capital goods is establishing itself, even on existing platforms, something that would once have been more typical of the consumer field.

Capital goods industries should not repeat the mistakes made by the B2C sector, that of refusing to follow the digitalization trend in sales and services. It is more important to see the development of digital industry platforms as an opportunity. “There is no room for being blindly pro-active. To start, a company must conduct a basic analysis of its performance portfolio. This will serve as a foundation on which to develop a platform strategy and, where required, new business models,” advises Thomas Rohrbach of Staufen Digital Neonex. A crucial aspect is also that of determining to what extent existing opportunities should be used, or whether a company should develop its own platforms. There is a trend among those study participants with experience in Industry 4.0 to develop in-house platforms. “However, this picture might change in the near future,” according to Rohrbach. “Diversification is recommended, especially in distribution. Companies should not unnecessarily limit themselves; instead, they should explore the myriad of offerings from the perspective of customer acquisition.”

German Industry 4.0 Index 2017

For the German Industry 4.0 Index 2017, Staufen AG, together with Staufen Digital Neonex GmbH, surveyed a total of 394 German companies. More than 70 percent of the companies surveyed were from the mechanical and plant engineering, automotive and electronics industry.

You can download the study and management summary here.

About Staufen Digital Neonex GmbH – www.staufen-neonex.de

Staufen Digital Neonex GmbH is a Staufen AG subsidiary that supports mid-sized manufacturers on the path to digital transformation. In addition to introducing hands-on digital strategies for mid-sized companies, topics such as smart factory, data science and digitalizing product programs or business models are also part of the program. Staufen Digital Neonex does not leave participants to fend for themselves. Uncertainty and possible mistrust are minimized through customized qualification programs. Because Staufen believes that even in a smart factory, it’s the people who make the difference.