THEN MASS, NOW CLASS – PRODUCTION WAS TURNED UPSIDE DOWN

From Ransbach-Baumbach northeast of Koblenz out into the world: Munsch Chemie-Pumpen GmbH delivers around 80 percent of its production abroad. What makes the pumps from this family business so unique: They are made entirely of plastic instead of metal as usual. This makes it possible, for example, to transport chemically contaminated liquids that would otherwise damage metal pumps. The company was founded by the father of the Managing Director in 1964. Currently, the company has 125 employees and generated sales of €27.5 million in 2017. Remarkably, nearly one tenth of annual sales is invested in research and development every year, whereas the industry average is only between four and six percent.

EMPLOYEES FEEL THEY ARE TAKEN SERIOUSLY AND VALUED

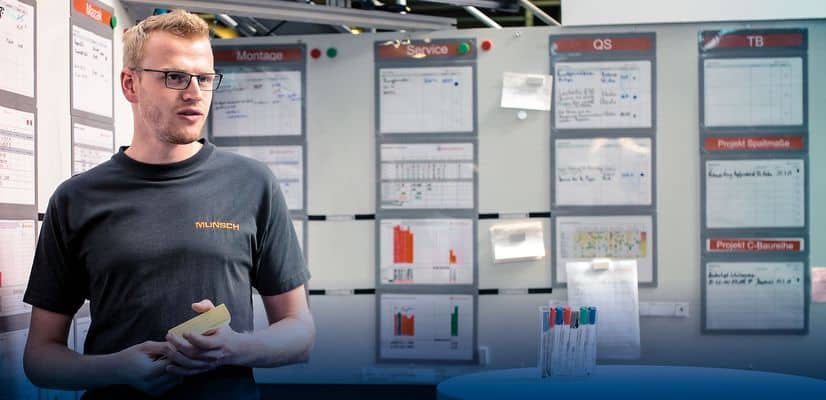

Along with the introduction of Shop Floor Management in manufacturing, a new management system was implemented. Until then, there had been no holistic system for this. At the beginning, employees and executives were not exactly enthusiastic about the plan. There was a fear of control. However, once the employees understood the meaning and purpose of Shop Floor Management in practice, these fears subsided. At its core, the new system is not about personal control, but about identifying deviations from the defined goal and taking measures to improve it. In short: If deviations are identified, measures are taken.

In fall 2017, the shop floor concept at Munsch was transferred to the first administrative area: sales. And the results are great: Thanks to the newly introduced deviation management, the sales staff have now also grown together to form a real team. Managing Director Munsch is satisfied with the results: “Today, we see the lean concept as a comprehensive qualification, training and improvement system. On the one hand, we use it for generating customer benefits. On the other, and just as importantly, for the satisfaction of our employees.”

With the financial crisis of 2009, the world changed completely as orders began to break away at Munsch. Until then, 70 percent of sales were achieved in a single industry with a limited portfolio of standardized pumps. Thanks to standardization, tehy had an excellent process flow in the areas of manufacturing and assembly. As orders began to slump, the company succeeded in winning new industries as customers with the help of product innovations.

The result: an explosion of product variance. Instead of standard pumps, custom-made pumps were now required. This impacted the previously good process flow. “The existing Kanban system reached its limits,” says Managing Director Munsch. The assembly area underwent restructuring according to lean criteria prior to 2007, while the product area remained untouched.